In continuum mechanics, a constitutive law is any relationship between stresses and strains. In other words, it is a macroscopic law that predicts how a material volume will deform knowing how it is constrained. These laws generally include a large number of parameters. They can be divided in two categories: phenomenological laws, in which the parameters have little physical meaning and are adjusted on the basis of experimental data, and physics-based laws, which are generally more complex to formulate but in which the parameters do have a physical meaning. It is this second approach that is explored in the laboratory.

The specificity of the laboratory is that it relies on a multi-scale strategy to free itself from phenomenological parameterisation: the information required at one scale is obtained at a finer scale, and so on. The transition between scales is ensured by a model at the larger scale that incorporates internal variables representative of the smaller scale. Crystal plasticity is an example of such a model, and involves several of the laboratory’s researchers. The irreversible deformation of metals is described through the behaviour of linear defects called dislocations. It is therefore necessary to know how dislocations evolve and how they interact with each other. Velocity laws for dislocations are calculated in Molecular Dynamics, while Discrete Dislocation Dynamics is used to obtain coefficients representing interactions between dislocations [1].

One of the concerns at the heart of these developments is to have a law that is valid over a wide range of strain rates. For example, the LMCE has developed a model based on mobile and immobile dislocation densities that has shown good reproduction of experimental results on tantalum for both moderate and high loading rates [2]. To further extend the possible uses of the models, studies are being carried out on the specific behaviour of dislocations at very high loading rates. In this field of elastodynamics, dislocations interact strongly with the stress fronts propagating in the material [3].

In some cases, the mechanisms that drive the deformation of the material are poorly understood, which makes it impossible to write physics-based constitutive laws. To overcome this limitation, Molecular Dynamics calculations can be used to estimate the energy cost of deforming the material in different directions, and to find the most favourable ones. In particular, this approach has been applied to an energetic material, TATB, and has made it possible to explain its behaviour through new deformation mechanisms [4].

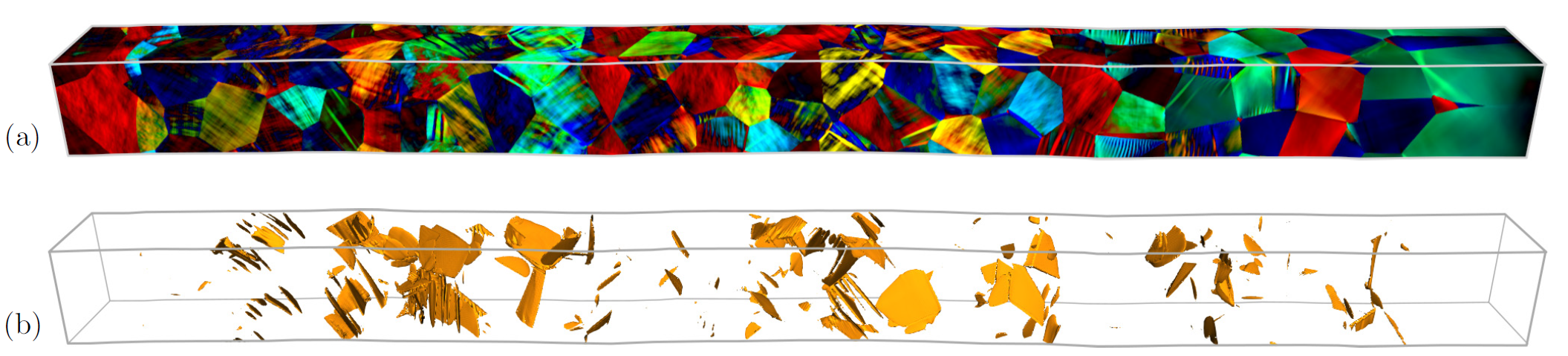

Figure 2:

ExaCoddex simulation of the compression of a TATB bar, including twinning and buckling deformation mechanisms

Publications

- R. Madec, L. Kubin, Dislocation strengthening in FCC metals and in BCC metals at high temperatures, Acta Mat. 126, 166-173 (2017) DOI

- C. Denoual, Y.-P. Pellegrini, P. Lafourcade, R. Madec, Dislocation storage-release-recovery model for metals under strain rates from 10^(-3) to 10^7 s-1, and application to tantalum, JAP 135, 045101 (2024) DOI

- Y.-P. Pellegrini, M. Josien, Shock-driven nucleation and self-organization of dislocations in the dynamical Peierls model, PRB 108, 054309 (2023) [DOI] (https://doi.org/10.1103/PhysRevB.108.054309)

- P. Lafourcade, C. Denoual, J.-B. Maillet, Irreversible Deformation Mechanisms for 1,3,5-Triamino-2,4,6-Trinitrobenzene Single Crystal through Molecular Dynamics Simulations, JPC C 122, 14954-14964 (2018) DOI

Researchers involved

P. Bouteiller, N. Bruzy, C. Denoual, J.-L. Dequiedt, A. Dubois, P. Lafourcade, R. Madec, J.-B. Maillet, Y.-P. Pellegrini